Il y a quelques années, j’ai eu le plaisir de visiter l’usine DJEVA et de découvrir un grand fabricant de saphirs et rubis synthétiques situé près de Montreux en Suisse. L’usine tourne 24 heures sur 24 et emploie près de 80 personnes.

L’histoire de Djeva remonte au début du 20ème siècle. En 1902, le lapidaire Hrand Djevahirdjian est interpelé par la publication des travaux du physicien Auguste Verneuil sur la synthèse du rubis.

Il essaie le procédé, le perfectionne, remplaçant le gaz d’éclairage par l’hydrogène et se lance dans la production de corindons de synthèse.

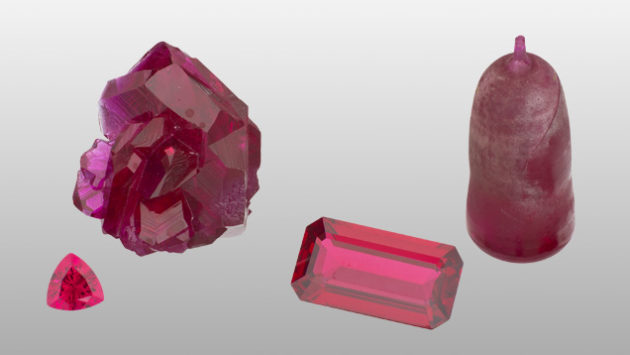

Qu’est-ce qu’un corindon synthétique ?

Le corindon synthétique est un corindon fabriqué en laboratoire avec les mêmes composants que la gemme naturelle. Connu en bijouterie fantaisie, ses applications industrielles sont innombrables et d’une grande valeur.

Le corindon est le nom scientifique des saphirs et des rubis, qui sont donc de la même famille de gemmes. Corindons naturels trouvés dans la nature ou corindons synthétiques produits en laboratoire ont exactement les mêmes propriétés physiques et chimiques et il faut des connaissances, un bon œil et souvent de bons instruments pour les distinguer.

C’est le chimiste français Auguste Verneuil, qui a mis au point sa synthèse en 1891. La formule chimique de cet oxyde d’aluminium est relativement simple : Al2 O3 , mais cela ne veut pas dire que chacun peut en fabriquer dans son garage !

Le corindon (naturel ou synthétique) parfaitement pur est incolore mais c’est assez rare et il existe dans quasiment toutes les couleurs de l’arc en ciel. Il suffit que quelques atomes d’aluminium soient remplacés par du fer, du cobalt, du titane, du manganèse ou du chrome ou une combinaison de ces éléments pour que le corindon se colore et devienne bleu, rose, jaune ou plus rarement rouge « rubis » quand, par chance, le cristal a incorporé du chrome, élément rare sur terre. Les plus connus sont le saphir bleu (une quasi redondance, puisque saphir vient du grec sappheiros, bleu) et le rubis (rubeux signifiant « rouge » en latin).

Pourquoi les Alpes ?

Originellement située près de Lyon puis dans les Pyrénées, l’entreprise s’installe finalement à Monthey en Suisse pour des raisons à la fois techniques et économiques.

La fabrication de saphirs synthétiques nécessite une énorme quantité d’énergie, industrie hautement consommatrice d’électricité, il est donc important qu’elle soit située dans une région où l’électricité est bon marché. Elle nécessite également du chlore et doit être installée à proximité de sites chimiques. Les gaz (oxygène et hydrogène) destinés à chauffer les ingrédients qui vont cristalliser et croître dans des moules réfractaires sont produits par électrolyse de l’eau.

Les 2 gaz sont stockés dans un impressionnant parc de réservoirs de 20 000 m³ sous pression et donnent une autonomie de 12 heures permettant de poursuivre la fabrication la nuit quand l’électricité est moins chère.

La consommation annuelle d’électricité de DJEVA équivaut à la consommation d’une ville de 8000 habitants !

Dans les bâtiments, Il y a 6 immenses salles de fabrication de corindons, où 2000 fours à chalumeau fonctionnent jour et nuit.

Comment « pousse » le cristal ?

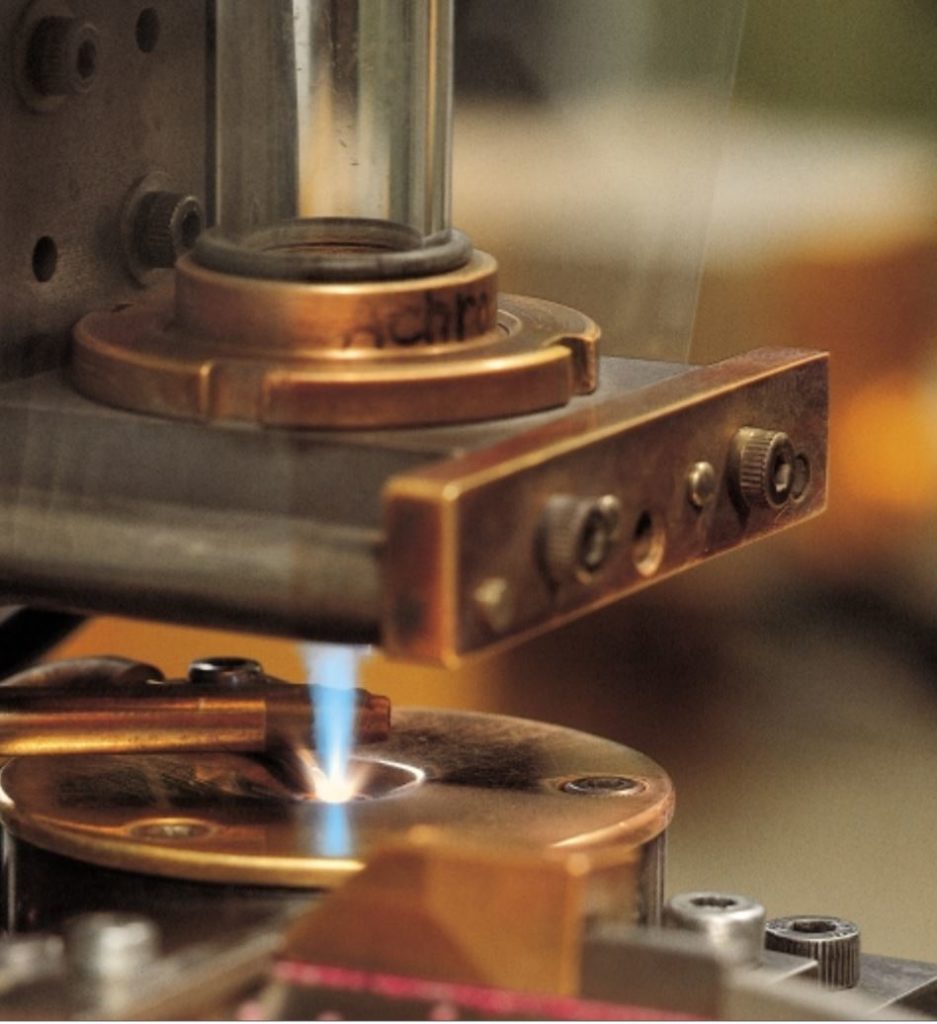

On part d’un germe de corindon synthétique orienté selon la future utilisation. La pierre croît comme une stalagmite. Un technicien règle l’arrivée d’hydrogène/oxygène des 45 chalumeaux, puis l’arrivée de poudre d’alumine grâce à un petit marteau réglé individuellement.

La vitesse de croissance de la « bouteille cristalline » est de 1 cm/h, vitesse plus rapide pour la couleur bleue. Nous apercevons un pierriste préparer sa cuisson, il porte des lunettes qui protège ses yeux de la flamme très aveuglante. Il est très concentré car la première heure est cruciale.

La fabrication des cristaux selon le procédé Verneuil se fait sous basse pression. Le cristal a une forme de bouteille renversée. A la fin de la croissance, il faut éliminer des tensions qui fragilisent le cristal, les bouteilles sont donc recuites à 1800° sans air, pendant 24/48 heures afin d’être stabilisées.

Comme l’indique sa formule chimique, l’alumine est le minéral de base des corindons, DJEVA produit leur propre alumine.

Les chalumeaux oxhydriques sont fabriqués sur place, de même que les « moufles », ces fours qui servent à protéger le cristal en cours de croissance. Les moufles sont composées de terre réfractaire et de chamotte.

Les moules réfractaires doivent supporter une température supérieure à 2000°. Le creuset agit comme un four qui protège les pierres. Chaque creuset peut servir entre 10 et 50 fois selon son diamètre ou le colorant utilisé pour la pierre car il y a des composants qui attaquent plus que d’autres.

Au bout de la chaîne, avant l’expédition, se trouve l’atelier de contrôle qualité où l’on détermine le plan de clivage de chaque corindon grâce à des polariseurs croisés. Le plan de clivage et la direction de l’axe optique seront indiqués sur chaque pièce. On traque ensuite les bulles, les éventuelles matières non fondues etc. Les pierres peuvent ensuite être mesurées, calibrées et stockées.

A quel usage est destinée la production ?

DJEVA vend des pierres brutes et des pierres percées au laser. Des cristaux Incolores pour les verres de montre ou les lentilles optiques, des colorés pour la plupart des autres applications.

Par exemple, les rubis sont percés et deviennent des rondelles destinées aux fabricants de montres ou aux industries de précision. Le trou mesure entre 34 à 39 microns de diamètre, l’équivalent de la moitié de celui d’un cheveu. Donc on ne cherche pas à le voir sans microscope.

Ces rubis percés (pierre extrêmement solide et résistante aux frottements) servent de base aux pivots en mécanique de précision. D’autres rubis seront taillés pour habiller des remontoirs de montres.

Nous passons rapidement l’atelier de fabrication des verres de montre, partant de la bouteille cristalline, on place le plan de clivage et on opère le sciage en arrosant d’eau.

Il faut à peu près quatre heures pour le sciage, puis on passe le « verre » dans une machine à abraser (abrasif diamanté) pour mettre les faces parfaitement à plat.

Le verre est ensuite poli par l’application de poudre de diamants de plus en plus fine…

DJEVA fabrique également des rubis et des saphirs synthétiques étoilés, un procédé délicat afin de diriger les aiguilles de titane pour former une étoile à 6 branches.

C’est un traitement de longue durée qui nécessite plusieurs semaines à des températures variées. Beaucoup de ces saphirs ou rubis de couleur, purs ou étoilés sont destinés à la bijouterie fantaisie et aux copies de bijoux précieux. DJEVA reste discret sur les fraudes possibles. Heureusement le consommateur français est assez protégé, mais pas le touriste sur un marché exotique qui ne pensera pas un instant que la belle pierre, si pure, puisse venir d’une usine si près de chez lui.

Les autres produits techniques de l’usine concernent les buses d’injecteur, des billes et des embouts d’endoscope. Il est passionnant de découvrir que les saphirs synthétiques entrent dans la fabrication des téléphones portables, des lentilles optiques scientifiques et des trains d’atterrissage d’Airbus… Bon vol !